CONCENTRATOR

In recent years, more and more people are concerned about the impact of environmental pollution by VOCs (Volatile Organic Compounds) on the human body. Although the movement to regulate VOC emission has been spreading throughout the world with the advance of industrialization, without making an effort there will be no silver-bullet breakthrough. We would like you to take a moment to think what we can do for coexistence of the environment and industrial development.

VOC concentrator can effectively purify and concentrate VOCs laden air stream exhausted from industrial factories. By being combined with incinerator or solvent recovery equipment, both initial and operating costs of the entire VOC abatement system can be drastically reduced

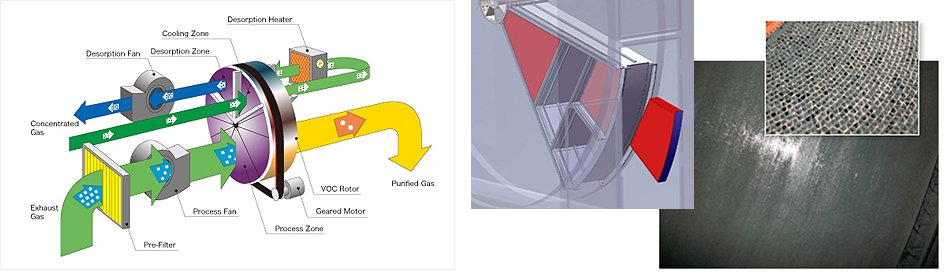

How to operate concentration rotors

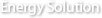

VOC concentration rotor is made of honeycomb inorganic paper as a substrate, in which the High-Silica zeolite (Molecular Sieve) is impregnated. The rotor is divided into 3 zones such as process, desorption and cooling zones by the casing structure and heat resistance air sealing. The rotor is constantly rotated at the optimum rotation speed by a geared motor

1. VOC laden exhaust gas passes through the process zone of the rotor being continuously rotated, and the incombustible zeolite in the rotor adsorbs VOCs and exhausts purified gas to the ambient.

2. VOC adsorbed part of the rotor is rotated to the desorption zone, where the adsorbed VOCs can be desorbed with small amount of high temperature desorption air and be concentrated to the high concentration level (5 to 20 times). Then, the high concentrated VOC gas is transferred to appropriate post treatment systems such as incinerators or recovery systems.

3. The desorbed part of the rotor is further rotated to the cooling zone, where the zone is cooled by the cooling gas. A part of VOC laden exhaust gas from the factory passes through the cooling zone and is transferred to a heat exchanger or a heater to be heated and utilized as desorption air.

High performance & efficiency

Using High silica zeolites and activated carbons with enormous adsorption capacity allows our VOC concentrator to flexibly treat various kinds of VOCs and work under different conditions of operation

Capability of treating VOCs with high boiling point

Carbon material has a difficulty to treat VOCs with high boiling point due to its desorption temperature limit. In contrast, the characteristics of our zeolite rotors are incombustible and high heat resistance, which enables our VOC concentrator to use the adsorption air with high temperature.

Inertness

VOC easily polymerized by heat energy (e.g. styrene, cyclohexanone, etc) can be effectively treated by High-Silica zeolite.

Clean-ability & activation by special heat treatment

Our zeolite rotors through calcining process have come to all inorganic material including the adhesive. Clogging in the rotor element might occur after a certain period of use.But, don’t worry!! The rotor is washable in a proper manner to remove accumulated dust. It’s even better that our zeolite rotor can be reactivated by heat treatment according to circumstances.